Malaysia’s longest bridge is helping boost social and economic development in the country’s northwest region, while also providing lasting resilience through pioneering anti-seismic technology.

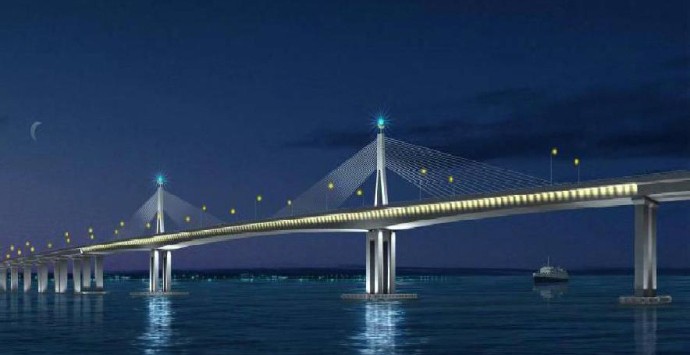

The Second Penang Bridge, also known as the Sultan Abdul Halim Muadzam Shah Bridge, is a 24-kilometer (14.9-mile) structure linking Penang to Peninsular Malaysia, and the largest civil engineering project in the region for the past 20 years.

The bridge has been as a key catalyst for the social and economic development of the Northern Corridor Economic region (NCER) and, upon completion in March 2014, became Malaysia’s longest bridge and the second-longest in Southeast Asia.

Specialist bridge capabilities

Beginning in 2008, AECOM worked with the China Highway Planning and Design Institute (HPDI), as consultant of China Harbour Engineering Company (CHEC), providing feasibility studies and detailed design as well as pre-tendering and post-tendering services and site supervision.

Our team in Malaysia, together with engineers from our long-span and specialty bridges group, worked on the design, construction supervision and construction engineering of the project. We also provided specialist consultancy on aerodynamics, navigation risk assessment and ship impact studies, seismic analyses, wind and structural health monitoring, fire hazard assessment and the resolution of construction challenges in the substantial marine piling operation.

Innovative ESG outcomes

A key feature of the Second Penang Bridge was the pioneering of new anti-seismic construction methods, which have minimized the risk caused by the Sunda tectonic plate, which straddles Southeast Asia. This in turn has brought more security and resilience to the region.

“The Second Penang Bridge is subject to the merciless forces of nature, such as earthquakes, potential tsunamis, and wind, to name a few; and is exposed to a hostile marine environment,” said Rd. Robin Sham, AECOM’s global long-span and specialty bridges Director. “These challenges were overcome through meticulous planning and design, and the result is one of the world’s largest sea-crossing projects in recent years. We have helped accomplish an immense human endeavour; creating many innovations along the way.”

The bridge is now the longest in the world to be installed with high-damping rubber bearings (HDRBs) for seismic isolation and the first of its kind in Malaysia to be installed with seismic expansion joints, which allow for movement during seismic activity.