PFAS sampling challenges & recommendations

The challenges associated with PFAS are many, ranging from understanding the complex range of compounds that make up PFAS, to providing regulatory criteria that ensure a safe environment is achieved.

With the release of the PFAS National Environmental Management Plan by the Heads of EPA nearly 12 months ago, understanding of these issues across the industry has become clearer. However, there are still things the industry and particularly environmental investigators should be aware of in order to improve the quality of their assessments and reduce the expense associated with the collection of irrelevant data.

Is the data of adequate quality for decision-making purposes?

Here are just a few key issues that we need to tackle in a systematic and sustainable manner:

- Representative environmental sampling, to ensure that data represent the actual characteristics and risks associated with a site

- Appropriate regulatory guidance for threshold levels for a range of environmental media (e.g. soil, water, biota, food)

- Appropriate monitoring tools (including setting safe levels for dust, food, consumer products and interpretation of blood levels)

- Appropriate analysis to quantify the degree and extent of the problem

- And many more…

Analysis ─ Are we making expensive decisions based on data of adequate quality?

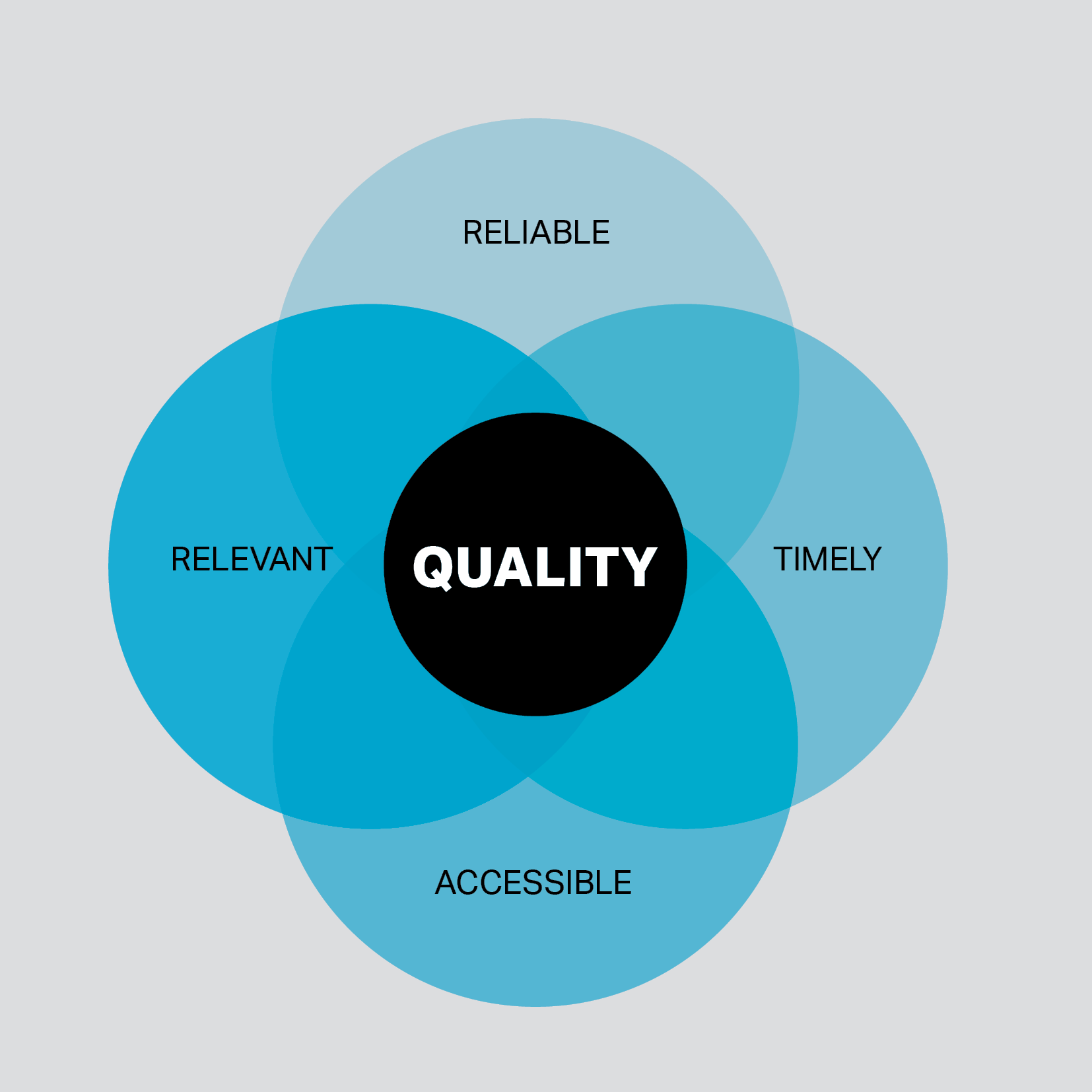

Decisions relating to PFAS contamination and its clean-up are typically expensive in terms of both time and cost. The information gathered to inform such decisions needs to be of adequate quality; however, not necessarily the ‘highest’ quality. The data for such decisions needs to be reliable, relevant, and provided in a timely and accessible manner. These are key considerations, to ensure that resources are not wasted chasing a level of quality that is not required.

The essential requirements for any environmental analysis need to include:

- High specificity for target compounds

- Detection limits below regulatory trigger criteria

- Reasonable sample volume (smaller is better)

- Reasonable throughput

- Low complexity (e.g. simple sample preparation and measurement)

- Relatively robust process.

The emerging automated analysis for PFAS is also providing a variety of advantages, including:

- Elimination of extensive and tedious manual handling steps that are known sources of error

- High data recovery

- Improved reproducibility

- High sample throughput

- Reduced exposure of lab staff to hazardous environments.

However, the rapid emergence of PFAS analysis to meet stakeholder demands has also increased the risk of reporting data that does not reflect the actual environmental concentrations rather than data of adequate quality, particularly in the examples outlined below:

- Systematic analytical measurement protocols may result in both under-reporting and over-reporting of results (e.g. previous PFAS reference material assumed PFAS was adequately represented by linear standards, or later by generically-derived standards, such as the 75 percent linear/25 percent branched reference materials; whereas the source of PFAS needs to be carefully considered to determine the appropriate reference materials to use). 1

- Systematic analytical instrumental protocols may also result in both under-reporting and over-reporting of results, such as in the use of mass spectroscopic techniques with mass-to-charge ratios.

- Analysis of environmental media (including water, soils, sediments, biota, food and blood) is a very complex issue and prone to ‘false-positive’ AND ‘false-negative’ results.

- PFAS is ubiquitous, so it will be present in the background and it has the potential to cause cross-contamination.

- PFAS history (e.g. early manufacturing using the ECF process, voluntary ceasing of production and the emergence of new substitutes such as GenX) have created chronological changes to PFAS, necessitating informed selection of PFAS analytical techniques.

- Appropriate analytical procedures that meet the essential requirements noted above are still under development.

- Regulatory guidance is also under development.

- Community expectations far exceed the scientifically-defensible development of sustainable responses to the PFAS challenges.

- The demand for data for decision-making purposes continues to increase.

- The scientific process may lead to the loss of stakeholder trust, as hypotheses are robustly tested and sometimes rejected.

Lessons learnt

Analysis for PFAS needs to be carefully designed by experienced professionals to ensure that the resultant data meets the project’s needs (i.e. designed using the Data Quality Objective Process).

A well-designed response to emerging contaminants is required, learning from previous approaches to these types of contaminants (e.g. PCBs, dioxins). Data must be reviewed by suitably experienced personnel to ensure that it is of adequate quality for the proposed decision-making purposes.

1 This issue was first raised by AECOM when our routine inter-lab quality control results were consistently reported higher for one contract lab, compared to the other. Further investigations uncovered that one lab only used linear reference material where the other used a mixture of 75 percent linear/25 percent branched, consistent with the assumed percentages derived from the ECF manufacturing process for certain PFAS.